Have you ever wondered how these colossal transformers effectively handle the electrical load they are entrusted with? Well, they are specifically designed in various sizes that are determined by their KVA rating—a crucial aspect as it determines their capability to transfer electrical energy at their maximum efficiency.

Transformers play a crucial role in electrical systems and are created to function at a specific power rating, depending on the projected load conditions and the application they are intended for. This applies to both industrial and residential settings, where transformers play a significant role in regulating voltage.

Understanding kVA Rating

The kVA (kilovolt-ampere) rating of a transformer refers to its capacity or power rating, which indicates how much power the transformer can handle or deliver. The transformer power rating is specified by its manufacturer and is based on the primary and secondary voltage ratings, as well as the maximum current that the transformer can handle.

Determining the appropriate size of a transformer is crucial and depends on the load it has to handle. To calculate the transformer’s load capacity, it is necessary to determine its kVA rating, which indicates its apparent power capacity, where the rating of the transformer is calculated by multiplying the voltage and current.

To calculate the rating for a single or three-phase transformer based on winding voltage and amperage information, you can use the following formulas:

| Transformer Type | Single phase transformer | Three phase transformer |

| Formula | kVA = (Volts x Amps) / 1000 | kVA = (Volts x Amps x 1.732) / 1000 |

Where:

- Volts: The voltage on the primary or secondary winding of the transformer, depending on which winding voltage and amperage information.

- Amps: The current flowing through the primary or secondary winding of the transformer.

- 1.732: A constant used in the three-phase transformer formula to account for the square root of 3, representing the phase difference between the three phases of the system.

Note: The above formulas calculate the apparent power of the transformer, which is related to the real power capacity (in watts) by the power factor. The power factor measures the efficiency of a transformer in converting electrical power from one voltage level to another. It is usually represented as a decimal between 0 and 1, and a low power factor can lead to a higher demand for current, which may require a larger transformer.

Example: Transformer Calculation

For single-phase transformer: Suppose you have a primary winding voltage of 240 volts and a primary winding amperage of 10 amps. The transformer’s kVA rating would be:

kVA = (240 volts x 10 amps) / 1000 = 2.4 kVA

If the power factor of the transformer is 0.8, the real power capacity of the transformer would be:

Real Power (Watts) = kVA x Power Factor = 2.4 kVA x 0.8 = 1.92 kW

For a 3-phase transformer: You have a line voltage of 480 volts and a line current of 20 amps, the kVA rating of the transformer would be:

kVA = (480 volts x 20 amps x 1.732) / 1000 = 16.64 kVA

If the power factor of the transformer is 0.9, the real power capacity of the transformer would be:

Real Power (Watts) = kVA x Power Factor = 16.64 kVA x 0.9 = 14.976 kW

These calculations can help you select the appropriate transformer size based on the expected load, avoiding potential equipment damage and efficiency losses.

Factors Affecting Transformer Capacity

1. Voltage Level

Calculating the voltage ratio of a transformer is essential for ensuring its proper sizing and performance. This ratio has a significant impact on the electrical characteristics of the system, and it’s crucial to ensure that the transformer’s capabilities align with the desired voltage levels. To calculate the voltage rating, divide the primary voltage by the secondary voltage.

For Example, if the primary voltage is 480V, and the secondary voltage is 240V, the voltage ratio would be 2:1 (480/240 = 2). This means that for every two volts on the primary side, there will be one volt on the secondary side.

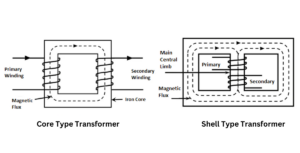

The primary and secondary windings of a transformer determine the voltage levels and influence the overall size requirements. The primary winding is connected to the power source, while the secondary winding provides the required output voltage. By properly selecting the primary and secondary winding voltages, you can achieve the desired voltage transformation and ensure an efficient amount of power transfer.

2. Load Requirement

The appropriate size of the transformer is determined through load requirements. The voltage levels, power factor and efficiency of the electrical system it serves are the factors that determine the transformer load capacity. By accurately estimating the load capacity of the transformer, you can select a transformer that can handle the expected electrical demand without operating at maximum capacity, ensuring longevity and performance.

For instance, if a facility has a 100 kVA load, a 75 kVA transformer won’t suffice. They are planning to add new equipment with a load of 50 kVA, which would bring the total load to 150 kVA. If the facility were to install the new equipment without upgrading the transformer, the transformer would operate at maximum capacity, leading to reduced efficiency and potentially damaging the equipment.

To avoid this scenario, the facility must upgrade the transformer to handle the increased load. Based on the load calculation, the total electrical load would be 150 kVA. It’s recommended to have a transformer that can handle up to 125% of the total load to ensure optimal efficiency and longevity of the equipment. Therefore, the facility would need a transformer with a minimum kVA rating of 188 kVA (150 kVA x 1.25).

3. Efficiency

The efficiency of the transformer is also a consideration when choosing a transformer size. Opting for a higher-efficiency transformer can improve performance and lower operating costs. Such transformers help to minimise energy losses, which has a positive impact on the environment and reduces overall expenses. It’s worth noting that transformers with lower temperature rise values tend to be more efficient. The reason behind this is that excessive heat can cause insulation damage and reduce the transformer’s lifespan.

Measuring the input and output power is necessary to calculate the transformer’s efficiency, and you can use the provided formula to do so.

Efficiency = (Output Power / Input Power) x 100%

4. Operating Conditions

The operation of the transformer is closely related to its sizing. The standard transformer has an ambient temperature specification of 30°C. Operating the transformer in extreme conditions may require derating, reducing its effective rating. For example, a transformer rated for certain power output at an ambient temperature of 40°C may need to be derated if it is installed in a location where the ambient temperature regularly exceeds 40°C.

Similarly, transformers operating at high altitudes or in harsh environments may require larger sizes or additional cooling methods to maintain optimal operating conditions and prevent premature failure. That’s why it is crucial to choose a transformer that operates within the acceptable temperature range, ensuring its reliability and longevity.

Seeking Expert Advice to Choose the Right Size of Transformer

Ensuring that the transformer size is precise and capable of meeting both current and future load demands is of utmost importance. By carefully evaluating the factors, an appropriate transformer size can be selected to handle the anticipated power load effectively.

Seeking guidance from a leading transformer manufacturer can help determine the ideal KVA rating for the transformer, and accurate calculations can be made to choose the most suitable transformer for the intended application. Grant Transformer will offer valuable assistance and expertise in navigating electrical systems, particularly in transformer sizing, due to its extensive experience. Reach out to us today and get a consultation with our professional team.