Transformers are essential components in power systems, responsible for transferring electrical energy from one circuit to another while changing the voltage levels. However, during this energy transfer, certain losses occur within the transformer, affecting its efficiency and performance. Understanding these losses is crucial for optimal transformer operation and maintenance.

In this article, we will explore the different types of losses that occur in a transformer.

4 different types of energy losses in a transformer

There are four main types of losses that will occur in the transformers.

1. Resistive or copper or ohmic loss

This loss is caused by the resistance of the copper wire used in the transformer windings. As the electrical current passes through the wire, heat is generated due to the resistance, thereby resulting in power loss. So these are known as resistive loss, the copper loss in the transformer or I2R loss where ‘I’ is the current passing through the windings and ‘R’ is the internal resistance of the windings.

These losses are present in both primary and secondary windings of the transformer and depend upon the load attached across the secondary windings since the current varies with the variation in the load, so these are the variable losses.

Therefore, the total resistive loss will be calculated by using the formula :

Pc = I12R1 + I22R2

where,

Pc = Power of the copper (Watt)

I1 and I2 = the primary and secondary windings of the transformer

R1 and R2 = the resistance of the transformer windings

2. Iron or Core loss

These losses occur in the transformer’s core and are generated due to variations in the flux. These losses depend upon the magnetic properties of the materials that are present in the core, so they are also known as iron losses or as the core of the transformer is made up of iron. These losses are also constant since they do not change like the load.

There are two types of iron losses in the transformer. They are eddy current loss and hysteresis loss.

Eddy current loss

Eddy currents are induced in the conducting parts of the transformer, such as the steel core or iron body, due to the changing magnetic field. As the alternating magnetic flux flows through the core and other conducting parts, it induces an electromotive force (Emf) and causes small circulating currents known as eddy currents. These currents dissipate energy in the form of heat, leading to power loss.

To minimise this current loss, transformers are constructed using thin, laminated sheets of iron. Each sheet is coated with an insulating varnish, which only forces the eddy currents to flow with individual laminations, reducing overall eddy currents in the core. These sheets are typically made from silicon-iron or nickel-iron alloys, which can be magnetised more readily than pure iron.

The total eddy current loss will be calculated by using the formula:

Pe = Ke Bmax2 f2t2 V

where,

Pe = Eddy current loss (Watt)

Bm = Maximum flux density (Wb/m2)

f = Frequency of supply

t = Thickness of lamination (meter)

V = Volume of the material (m3)

Ke = Eddy current constant

Hysteresis loss

This loss is caused by the magnetism that remains in a material after the magnetising force has been removed. When the iron core of a transformer is subjected to a magnetic field, the magnetic domains within the core align with the field. As the polarity of the field changes, the magnetic domains must realign, resulting in power loss due to friction and heat generation.

The frequency of magnetic reversals, the volume and grade of the iron, and the value of flux density contribute to the hysteresis loss. Transformers can reduce hysteresis loss by using highly permeable magnetic core materials such as CRGO – Cold rolled grain-oriented Silicon Steel.

The total hysteresis loss will be calculated by using the formula:

Ph = ղ Bmax1.6 f V

where,

Ph = Hysteresis loss (Watt)

ղ = Steinmetz’s constant

Bmax = Maximum flux density (Wb/m2)

f = supply frequency

V = volume of the materials (m3)

3. Stray or flux loss

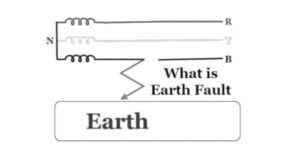

We are all aware that a transformer works on the mutual induction principle, where the alternating current in the primary winding generates magnetic flux lines through EMF induced in the secondary winding. However, in real-time, not all of the flux generated by the primary side is linked to the secondary side. This is known as flux leakage, and it causes losses in the transformer, lowering the output power. This form of loss can also be referred to as flux loss or stray loss.

The transformer’s primary and secondary windings must be wounded so that flux coupling between the coils is maximised. This approach may ensure maximum power transmission from primary to secondary during flux connections, reducing flux losses.

4. Dielectric loss

This loss is caused by the transformer’s insulating material. Transformer oil is typically used as a dielectric medium. The strength of the dielectric decreases when the transformer operates continuously. When the quality of the oil deteriorates, it causes some losses known as dielectric losses, which reduce the transformer’s overall efficiency. Regular inspections of the dielectric medium’s quality and condition can assist in preventing such losses.

Grant Transformer: Your Partner in Transformer Excellence

Transformers are the essential components in electrical systems, enabling the efficient transmission and distribution of electrical energy. However, losses in transformers result in reduced efficiency. At Grant Transformer, a leading transformer manufacturer in Australia, we understand the types of losses, such as iron, copper, stray and dielectric losses, which are crucial for optimising transformer performance. Our expertise in the field, with a deep knowledge of types of transformer losses, will help with design, material selection, and maintenance practices.

Contact us today if you would like to consider our transformers for your business or if you need any service or repairs.