Are you facing the dilemma of choosing between a dry type and an oil-filled transformer? If you find yourself at this electrical crossroads, fear not. This comprehensive guide will unravel the intricacies of these two transformer types, helping you make an informed decision that aligns perfectly with your requirements.

Transformers are the silent heroes of power transmission that facilitate efficient power transmission across vast distances. They hold the power to alter voltage levels, enabling electricity to travel far and wide. Their choice depends on safety concerns, environmental considerations, installation location, and long-term operational costs. Also, the voltage and capacity a transformer can withstand, the cooling mechanisms it employs, and even the materials used in its manufacture are key factors that set these two types apart.

Dry-Type Transformers: The Eco-Friendly Powerhouse

Dry transformers are synonymous with environmental friendliness. They are stationary, motionless equipment that utilises insulation systems that are kinder to the planet. These transformers rely on air for cooling, making them energy-efficient and eco-friendly. This cooling process eliminates the need for potentially harmful oil-based cooling systems.

Applications: Dry-type transformers find applications in various settings, including commercial, industrial, and utility environments. They are commonly used in small and medium-voltage applications for various electric equipment.

Dry Transformers Types: Various types cater to diverse needs within the realm of dry-type transformers. Each variant offers unique advantages, from Vacuum Pressure Impregnated (VPI) to Open Wound transformers.

Advantages of Dry-Type Transformers

- Safe High Voltage Handling: Dry-type transformers safely manage high voltage levels without transformer oil.

- Resilience to Overloads: This transformer doesn’t overload and prevents overheating, ensuring continuous operation.

- Low Maintenance: The absence of transformer oil simplifies maintenance, reducing costs and efforts.

- Clean Operation: No transformer oil means no risk of oil leaks or spills, contributing to a cleaner environment.

- Flexible Installation: They can be installed in various settings, catering to both high and low-voltage requirements.

- Reliable Voltage Rating: These transformers consistently maintain their voltage rating.

- Resin Insulation: Using resin for insulation enhances safety and reliability.

- Minimal Risk of Overheating: Effective insulation and design prevent overheating issues, ensuring optimal performance.

- Efficient Power Transformers: They efficiently transfer power, maintaining high reliability in different applications.

Drawbacks of Dry-Type Transformers

- Power Limitations: Not suitable for high voltage/power like larger oil-filled transformers.

- Higher Cost: Initial cost is higher.

- Cooling Efficiency: Cooling capability is lower, limiting high-capacity use.

- Size Complexity: Large units might need intricate cooling, affecting design.

- Temperature Sensitivity: Might operate at higher temperatures.

- Noise Generation: Can produce more noise during operation.

- Limited Overload Capacity: Not as resilient to short-term overloads.

- Compatibility Concerns: Replacing oil-filled with dry-type might need modifications.

- Application Constraints: Unsuitable for demanding insulation/cooling needs.

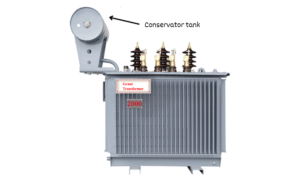

Understanding Oil-Filled Transformers: Cooling with Efficiency

Oil-filled transformers are synonymous with efficient cooling. Their structure involves an oil-immersed system that efficiently dissipates heat, ensuring optimal performance. The heat generated by the coil and iron core is transferred to insulating oil, which then disperses it to the cooling fluid. This intricate cooling process ensures smooth operations even in demanding situations.

Applications: Oil-filled transformers are widely used in outdoor installations, such as transmission and distribution lines, renewable energy generation, and large-scale industrial applications.

Oil Transformer Types: Oil-immersed transformers come in two primary types: 1-Phase and 3-Phase transformers. Their versatility allows them to serve various temperatures of the transformer environment, from power stations to renewable energy setups.

Advantages of Oil-Filled Transformers

- Longevity: Properly maintained, these transformers have a longer lifespan.

- Stable Performance: Resists overheating, ensuring consistent operation.

- Versatile Applications: Suitable for various scenarios due to high voltage rating.

- Proven Reliability: Power transformers using oil are widely employed and reliable.

- Smooth Operation: Performs well under varying load conditions.

- Enhanced Power Capacity: Ideal for high-power applications due to effective insulation.

- Low Voltage Compatibility: Works efficiently at low voltage levels.

Disadvantages of Oil-Filled Transformers

- Maintenance Demands: Regular maintenance of transformer oil is necessary.

- Environmental Concerns: Risk of oil leakage impacting the environment.

- Complex Design: Complexities arise with high-power and high-voltage setups.

- Costly: Initial and ongoing costs related to maintenance and oil.

- Compatibility Constraints: Not suitable for all applications due to its specific features.

- Heat Generation: Oil-filled transformers can generate excess heat during operation.

- Safety Risks: Risk of fire and leakage due to oil.

- Resin Vulnerability: Resin-encapsulated components may degrade over time.

- Oil Sampling Needs: Regular sampling is required to monitor oil quality.

Dry Type Transformer vs Oil Type Transformer: Comparing the Differences

In the arena of electrical equipment, the ongoing debate between the two types of transformers, dry-type transformers and oil-filled transformers, has sparked a quest for a better choice. For a detailed insight into Transformer manufacturing and supply, you can head to products and services offered by Grant Transformers.

Let’s delve into the intricacies of these two transformer types, comparing their differences to shed light on their unique features and applications.

Cooling Medium: Air vs. Oil

Dry-Type Transformers: The reliance on air for cooling in dry-type transformers makes them inherently efficient in dissipating heat. Air is readily available and serves as a cost-effective cooling solution. However, this efficiency has limits, restricting the voltage capacity of dry-type transformers to around 35kV due to cooling constraints.

Oil-Filled Transformers: Oil’s remarkable heat transfer capabilities make it a favoured cooling medium for oil-filled transformers. As the transformer’s internal components heat up during operation, the heat is transferred to the insulating oil, dissipating it efficiently. This allows oil-filled transformers to handle higher voltage levels and offers superior performance in demanding environments.

Maintenance: Regular Care vs. Infrequent Attention

Dry-Type Transformers: One of the advantages of dry-type transformers is their resilience and reduced need for regular maintenance. These transformers are inherently less prone to issues caused by oil degradation, such as chemical contamination. Consequently, dry-type transformers often require less frequent maintenance checks, saving time and resources.

Oil-Filled Transformers: Conversely, transformers filled with oil demand more attention. The oil used for cooling and insulation needs regular monitoring to ensure its quality and effectiveness. Periodic testing for chemical contamination and scheduled oil filtration is essential to maintain optimal performance and extend the transformer’s lifespan.

Operational Costs: Energy Efficiency vs. Operational Expenditure

Oil-Filled Transformers: Oil-immersed transformers might incur higher initial costs due to the oil’s involvement and the associated safety measures required for outdoor installations. However, these costs are often offset by the transformers’ energy efficiency. The efficient cooling provided by oil contributes to better heat dissipation, reducing energy losses and operational expenses over time.

Dry-Type Transformers: Although dry-type transformers typically have lower initial costs and require less maintenance, their energy efficiency might differ from their oil-filled counterparts. The air-based cooling mechanism, while efficient, might lead to slightly higher energy consumption in the long run.

Environmental Impact: Comparing Footprints

Dry-Type Transformers: Dry-type transformers stand out for their environmentally friendly nature. The absence of oil eliminates the risk of oil leaks and spills, reducing the potential environmental harm. This makes them a preferred choice for indoor installations and settings where ecological impact is a significant concern.

Oil-Filled Transformers: While oil-filled transformers offer exceptional performance, their reliance on oil introduces a potential environmental hazard. The risk of oil leaks and the need for oil containment measures make them better suited for outdoor installations where ecological protection measures can be more effectively implemented.

Role of Recycling in Transformer Manufacture

Recycling is crucial in the sustainable production of transformers, particularly oil-filled and immersed transformers. These liquid transformers, often designed to handle maximum voltage loads, require oil for optimal insulation and cooling. Recycling materials like copper and steel makes the manufacturing process more environmentally friendly.

Reusing components from decommissioned transformers, such as those that no longer require oil, can significantly reduce waste and conserve resources. Embracing recycling practices aligns with eco-conscious principles and ensures that the transformer industry continues to meet the demands of an environmentally responsible and energy-efficient future.

At Grant Transformers, a leading transformer manufacturing company, we recognise the importance of sustainability in transformer production. By incorporating recycled materials and advocating for responsible manufacturing practices, we contribute to a cleaner and greener energy landscape while delivering high-performance transformers that meet industry standards.

Need Transformer Repair, Refurbishment, or Customization? Contact Us Today

Making an Informed Decision: Selecting the Right Type Of Transformer

When it comes to designing a power system, making an informed decision about transformer selection is substantial. By assessing Your energy requirements, weighing environmental impact, and balancing safety and efficiency, you lay the foundation for a choice that resonates with your unique demands.

Turning to Grant Transformers can be a strategic choice while you consider the task of selecting the right transformer. Our expertise, range of offerings, and commitment to sustainable solutions make us an ideal partner for your transformer needs.

Contact Us Today and discover how we will transform your power system.